Wet Pendulum Device

The principle of the Wet Pendulum Tester to asses the friction characteristics of each specimen by determining the wet dynamic friction between the specimen and the slider of a pendulum swinging in a vertical plane.

|

|

Photos courtesy of Slip Check Pty Ltd

The Wet Pendulum Test is the de-facto in-situ test device. The device is calibrated in every 12 months to ensure accuracy of the test.

The slider rubber surface of the device has to be conditioned prior to each testing. This is done using a grade P400 abrasive paper.

There are two types of slider materials in use;

- Four S rubber (simulated standard shoe sole)

- TRRL (Transport Research Laboratory) rubber

Once the device is ready for testing, it is tested according to the relevant standard specifications.

The results are recorded and a slip resistance test certificate is issued.

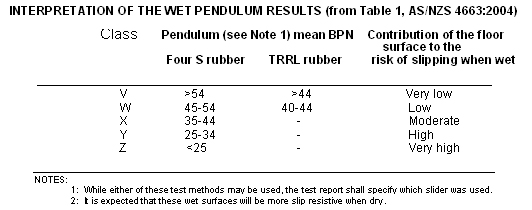

The table below will interpret the results and the certificate will nominate the corresponding classification as well.

Please note that only a NATA (National Association of Testing Authorities) acredited tester can issue a valid certificate.

As part of our commitment to provide you with a total floor safety solution, Global Safe Technologies recommends the following companies for your floor surface slip resistance testing;

Slip Resistance Testers Locator

(Select a State on Map Below)